SmartMeasurment - Corioris Mass Flow Meter

SmartMeasurment - Corioris Mass Flow Meter

With a Coriolis meter the fluid is directed through a vibrating flow tube

by factory frequensy active sensore

Coriolis forces exerted by the moving fluid cause the tube to twist.

The amplitude of the twist is related directly to the mass flow rate.

Phase between sensor signel related directly to the Density for liquid.

Coriolis meters are not very sensitive to swirl and asymmetry

but are affected by incorrect installation. and Coriolis is not require straight run pipe

When install a Coriolis meter into your piping system you need to

ensure that the vibrating tubes are aligned and not under stress

so that they twist and contort otherwise you will get errors.

-

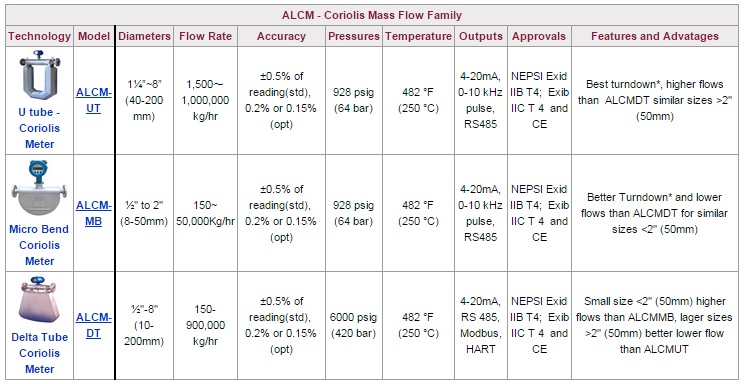

ALCM-DT

ALCM-DT

SMC’s ALCM-DT Delta Tube Coriolis Mass flowmeter makes use of delta, or triangle shaped

measuring tubes in a parallel arrangement. The delta tube geometry provides excellent low-flow performance versus other coriolis tube geometries, making this instrument an ideal choice for applications with smaller line sizes and lower flow rates. The ALCM is offered in line sizes ranging from ⅛” (3mm) to 8” (200mm) and is capable of measuring flow rates from 26 to 2,000,000 lbs per hour at accuracies of up to 0.15% of reading.

The ALCM-DT features an easy-to-read LCD display that can be configured to display either mass or volumetric flow rates in a variety of user-selectable engineering units as well as density, temperature, and totalized flows. This meter offers excellent value by providing a highly accurate, compact instrument that can measure flow, density, and temperature in a single package that has lower cost, lower pressure differential and a more compact design versus competitive coriolis technology flow meters. The unique combination of features and benefits offered by the ALCM-DT make it an ideal choice for applications that are found in a variety of industries including Food & Beverage, Petrochem, Oil & Gas, Paint, and Industrial Process Control. -

ALCM-MB

ALCM-MB

SMC’s ALCM-MB Micro-Bend Coriolis Mass flowmeter employs a unique tube arrangement with U-shaped measuring tubes that are formed with a significantly smaller radius versus traditional U-tube type coriolis meters. The more gradual radius of the ALCM-MB’s tube geometry provides for a more compact design and significantly reduced pressure differential versus other coriolis meters.

The ALCM-MB features an easy-to-read color OLED display that can be configured to display either mass or volumetric flow rates in a variety of user-selectable engineering units as well as density, temperature, and totalized flows. This meter offers excellent value by providing a highly accurate, compact instrument that can measure flow, density, and temperature in a single package that has lower cost, lower pressure differential and a more compact design versus competitive coriolis-technology flowmeters. The unique combination of features and benefits offered by the ALMC-MB make it an ideal choice for applications that are found in a variety of industries including Food & Beverage, Petrochem, Oil & Gas, Paint, and Industrial Process Control. -

ALCM-UT

ALCM-UT

SMC’s ALCM-UT uses two tubes formed into a U-shaped geometry in a parallel arrangement which are vibrated at their resonant frequency by coils.

Any mass flow passing through the tubes will generate coriolis forces, which appear whenever a mass moves radially in a rotating system.

The forces have opposite effects on the inlet and outlet side, deforming each pipe by a minor amount. The excursion of the pipes is detected by the inlet and outlet-side sensors. The phase shift between the rotational frequencies of both pipes is directly proportional to the mass flow rate and the resonant frequency of both pipes changes in accordance with the density of the fluid media. This effect allows for measurement of the density. Using only one sensor, both density and temperature measurements may be performed as the extent of deformation of the pipes is temperature-dependent. Therefore, the temperature is measured for compensation purposes.

Using only one primary sensor, values including mass flow, density, and temperature may be measured. The ALCM's microprocessor-based circuitry allows for conversions such as volumetric flow and % concentration to be calculated.

Coriolis Flow Meters